Dec. 11, 2023

Industrial Panel PCs are critical components in various industrial applications, providing a versatile interface for control and monitoring systems. Choosing the right Industrial Panel PC involves considering several factors to ensure it meets the specific requirements of your industrial environment. Here's a comprehensive buying guide to help you make an informed decision.

Understand Your Application: Identify the specific industrial application for which you need an Industrial Panel PC. Different industries have unique requirements, such as manufacturing, automation, or process control. Ensure the chosen Panel PC aligns with your application needs.

Processor Specifications: Assess the processing power required for your industrial tasks. Consider factors like CPU speed, number of cores, and compatibility with the software applications you'll be running. Choose a Panel PC with sufficient processing capabilities to handle your workload efficiently.

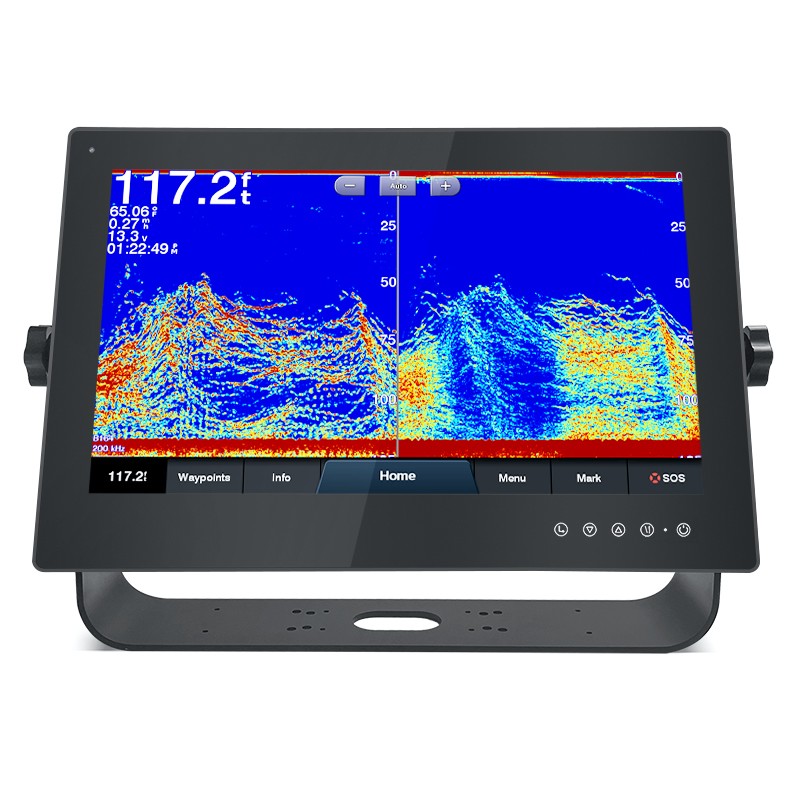

Screen Size and Resolution: Determine the ideal screen size and resolution based on your application's visual requirements. A clear and appropriately sized display is crucial for effective monitoring and control. Consider factors like touchscreen capability for user-friendly interactions.

IP Rating: Industrial environments can be harsh, with exposure to dust, moisture, and temperature variations. Check the Ingress Protection (IP) rating of the Panel PC to ensure it meets the environmental conditions of your facility. Higher IP ratings indicate better protection against dust and water ingress.

Ports and Interfaces: Evaluate the connectivity options provided by the Industrial Panel PC. Ensure it has the necessary ports and interfaces for connecting to other industrial equipment, peripherals, and networks. Consider USB, Ethernet, HDMI, and serial ports based on your connectivity needs.

Mounting Flexibility: Consider the mounting options that suit your industrial setting. Industrial Panel PCs offer various mounting configurations, including panel mount, VESA mount, or rack mount. Choose a mounting option that integrates seamlessly with your facility's layout.

Build Materials: Assess the build quality and durability of the Industrial Panel PC. Look for robust materials that can withstand vibrations, shocks, and other challenging conditions. A ruggedized design ensures longevity in demanding industrial environments.

Scalability Options: Consider whether the Panel PC allows for customization and future expandability. Industrial needs may evolve, and having a system that can accommodate additional features or upgrades ensures long-term flexibility and usability.

A: Yes, you can, but it depends on the IP rating of the Panel PC. Look for a higher IP rating, such as IP65 or IP67, for protection against water and dust ingress.

A: Touchscreen Panel PCs enhance user interaction, making it more intuitive and efficient. They are especially beneficial for applications that require quick responses and easy navigation.

A: The upgrade frequency depends on technological advancements and changes in your industrial processes. Consider upgrading when your current system no longer meets performance or compatibility requirements.

In conclusion, selecting the right Industrial Panel PC involves understanding application requirements, assessing performance, considering display characteristics, accounting for environmental conditions, evaluating connectivity options, choosing suitable mounting options, ensuring durability, and exploring customization possibilities. By addressing these factors and staying informed, you can make a well-informed decision for your industrial control and monitoring needs.

Custom Industrial Panel PCs for Specialized Applications

Nov. 21, 2025

How Do Touchscreen Monitors Enhance Productivity?

Nov. 18, 2025

24 inch Touch Panel PC Core I5-9400 GPU GTX 1050

Intel Core i5-9400 desktop processor with RAM DDR4 8GB and SSD 128GB.

Industrial Panel PC IP69k Stainless Steel 304 Enclosure 7x24h

EETI waterproof solution, touch can work well with drop water on screen.

Intel Alder Lake 12th Processor Embedded Mini Computer 6COM 6USB

2*HD-MI,1*Type-C,support synchronous/asynchronous triple display.

17 Inch Full IP67 Waterproof All In One Panel PC 12th Intel Core I3-1215U

17" 1280*1024 LCD Panel 1000nits, Optical bonding between touch screen and LCD screen

Industrial All In One PC Windows 11 pro SC800M

Intel 10th Celeron J4125/J6412 processor, optional Intel 8/10/11th Core i5/i7, support Windows 11.