Nov. 10, 2025

The Round-the-World Yacht Race, known as the "marathon on the ocean," is not only a stage for humans to challenge themselves and conquer nature, but also a "touchstone" for cutting-edge marine equipment. During the tens of thousands of nautical miles of transoceanic voyage, yachts face numerous challenges such as fierce storms, extreme temperature differences, and salt spray corrosion. Every decision made by the crew—whether it is adjusting the route, evading storms, planning supplies, or formulating tactical strategies—relies on one core piece of equipment: marine displays. Like the "intelligent eyes" of the yacht, they transmit accurate data and provide clear visibility in the ever-changing marine environment, becoming an "invisible comrade-in-arms" that determines the race's outcome.

1. A "Reliable Pillar" in Extreme Environments: The Hardcore Adaptability Behind the Specifications

The operating environment of the Round-the-World Yacht Race imposes extremely harsh requirements on equipment durability. From the high temperature and humidity in equatorial waters to the freezing cold in the Southern Hemisphere, from salt spray corrosion on the deck to violent turbulence amid wind and waves, ordinary displays would quickly fail. However, the "survival capability" of professional marine displays lies in the meticulous design of every key specification.

First is the all-dimensional environmental protection design. The marine display for the race adopt an IP67 waterproof standard for the whole unit as the core protection criterion — according to the International Electrotechnical Commission (IEC) standard, IP67 means the device is completely dustproof (IP6X dust protection level) and can be immersed in 1 meter of water for 30 minutes without affecting normal operation. This feature perfectly adapts to the extreme scenarios of the yacht race: when waves stirred by force 10 winds splash the deck, or temporary water accumulation occurs in the cockpit due to heavy rain, the display can work normally without additional shielding, completely avoiding the risk of failure of ordinary equipment due to water ingress and short circuits. Equipped with an anti-salt spray corrosion coating and sealing technology, the device has passed the salt spray test in the international maritime IEC 60945 standard, capable of resisting component erosion caused by high-humidity marine air and splashing waves. It can operate stably for a long time even in the salt spray-intensive environment of the "Roaring Forties" in the Southern Hemisphere. Meanwhile, the shockproof structural design allows the device to withstand tens of degrees of inclination and high-frequency vibration of the yacht in force 10 winds, with no risk of loosening internal components, completely avoiding fatal failures such as black screens and freezes. For deck installation scenarios, its lightweight feature significantly reduces the load-bearing pressure on the fixed structure. Combined with quick-install interfaces, the crew can complete disassembly and reinstallation within 30 minutes, meeting the demand for equipment position adjustment during the race.

Second is the all-weather visual support system. The screen adopts a 15.6-inch optimal size, which not only ensures sufficient display area in the limited space of the cockpit but also does not block the crew's view of the deck environment. Core visual specifications are tailor-made for marine scenarios: 1500nits ultra-high brightness paired with an AG anti-glare coating. Compared with ordinary commercial displays (with a brightness of 300-400nits), it can completely offset the strong glare from the sun on the sea surface—even when looking directly toward the sun, the crew can still clearly read data. Meanwhile, the minimum brightness adjustment capability of 30nits solves the light pollution problem during night navigation: the crew can check electronic charts without turning off the display, avoiding damage to night vision ability caused by strong light. Additionally, the Optical bonding process eliminates the air gap between the screen and the glass, fundamentally preventing fogging and condensation in high-humidity environments, and ensuring clear visibility from the equatorial doldrums to the edge of the Antarctic Circle.

2. The "Data Hub" for Race Victory: How Specifications Enhance Operation and Decision Efficiency

If durability is the "basic quality" of marine displays, then accurate and efficient data presentation and interaction are their "core competitiveness" in helping the crew win the race. During the Round-the-World Yacht Race, the crew needs to grasp a large amount of critical information in real time, and the specification design of this marine display makes data processing and operational response more in line with race needs.

High-definition data visualization is its core advantage. The 1920*1080 full HD resolution allows the screen to display multiple types of key data in divided areas simultaneously: the left side accurately shows core GPS navigation data (such as latitude, longitude, and speed), the right side synchronously presents real-time readings from anemometers and depth sounders, and the bottom lists race rankings and route turning point markers. This multi-dimensional data integration eliminates the need for frequent page switching. This high-definition display capability is particularly crucial in radar-linked scenarios—dynamic trajectories of distant ships and precise locations of reefs can be presented with millimeter-level clarity, providing a reliable basis for obstacle avoidance decisions during severe storms.

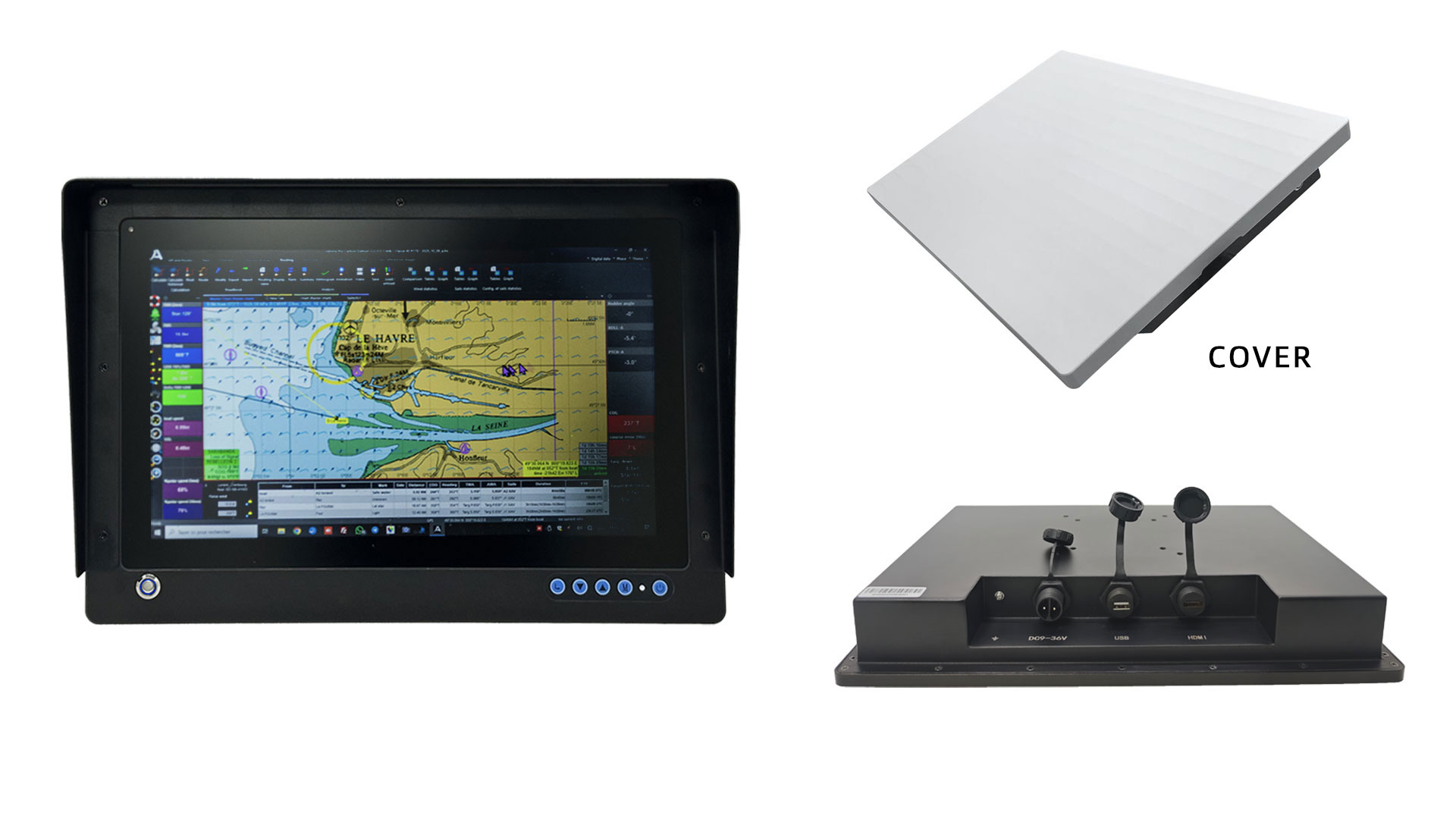

User-friendly interaction design further improves race efficiency. The screen adopts waterproof capacitive touch technology, breaking the limitations of ordinary capacitive screens: even when the crew wears gloves or has wet hands, they can achieve precise touch control—tapping to zoom in/out of electronic charts and swiping to switch data interfaces, with a response delay of less than 50 milliseconds. Equipped with custom touch-sensitive control buttons, the crew can call up frequently used functions with one tap, avoiding accidental touches on other options amid turbulence. Moreover, the combined design of a custom metal sunshade and a custom white protective cover provides double protection: the sunshade enhances visibility under direct midday sunlight, while the protective cover isolates splashing waves and debris when the device is idle or in harsh weather, balancing functionality and protection. This "hardware + interaction" specification synergy enables the crew to efficiently operate data even when their hands are busy adjusting sails or steering.

3. From the Racecourse to the Industry: Technological Evolution Driven by Specification Iteration

The Round-the-World Yacht Race is not only a "testing ground" for equipment but also a "catalyst" for technology. The specification configuration of this marine display is a typical example of technological upgrading driven by race demands, and these optimizations derived from the racecourse are also feeding back into the entire marine equipment industry.

For instance, the wide-range brightness design (1500nits to 10nits), initially developed to address the day-night visual needs of the Round-the-World Yacht Race, has now become a standard feature for commercial ocean-going cargo ship displays. The combined solution of waterproof capacitive touch and Optical bonding technology is also widely applied in fish-finder displays for coastal fishing boats, allowing fishermen to operate precisely in humid working environments. Additionally, the lightweight and shockproof structural design provides technical references for the portable installation of small yachts. These specification standards, refined through race scenarios, are enabling more marine navigation scenarios to benefit from more reliable and intelligent display technology.

Every departure of the Round-the-World Yacht Race is a tribute to human courage and technological strength. With a 15.6-inch full HD screen as its carrier, this marine monitor uses precise specifications such as full IP67 waterproof, 1500nits high brightness, waterproof touch control, salt-spray resistance, and shock-proofing to build a "visual defense line" against extreme environments and a "data hub" for efficient decision-making. It is not only a professional piece of equipment tailored to race needs but also a epitome of human efforts to explore the ocean and challenge limits—when hardcore specifications meet the passion for the ocean, they create a legend of cutting through waves. As technology continues to iterate, these race-derived specification standards will surely light up a clearer and more reliable path for future Round-the-World Yacht Races and the entire marine navigation industry.

Previous: The Industrial Panel PC empowers Dimensioning Solutions

Next: None